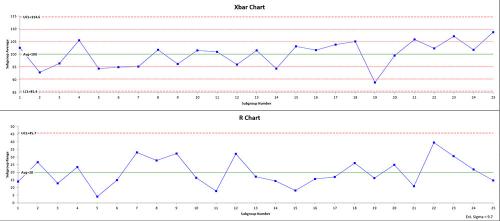

If small shifts in the process are of interest, you can use Test 2 to supplement Test 1 in order to create a control chart that has greater sensitivity. Test 1 is universally recognized as necessary for detecting out-of-control situations. Standard deviations from center line Test 1 identifies subgroups that are unusual compared to other subgroups. Each of the tests for special causes detects a specific pattern or trend in your data, which reveals a different aspect of process instability. LCL = XDBLBAR - A(2)*RBAR = 2.000-1.023*.0005 = 1.Use the tests for special causes to determine which observations you may need to investigate and to identify specific patterns and trends in your data. The following data consists of 20 sets of three measurements of the diameter of an engine shaft. using an average run length (ARL) for determining process anomalies four out of five points that are on the same side of the centerline, four at a distance exceeding 1 sigma from the centerline f. two out of three points that are on the same side of the centerline, both at a distance exceeding 2 sigmas from the centerline e. six successive points that increase or decrease d. eight successive points on the same side of the centerline c. one point outside the 3 sigma control limits b.

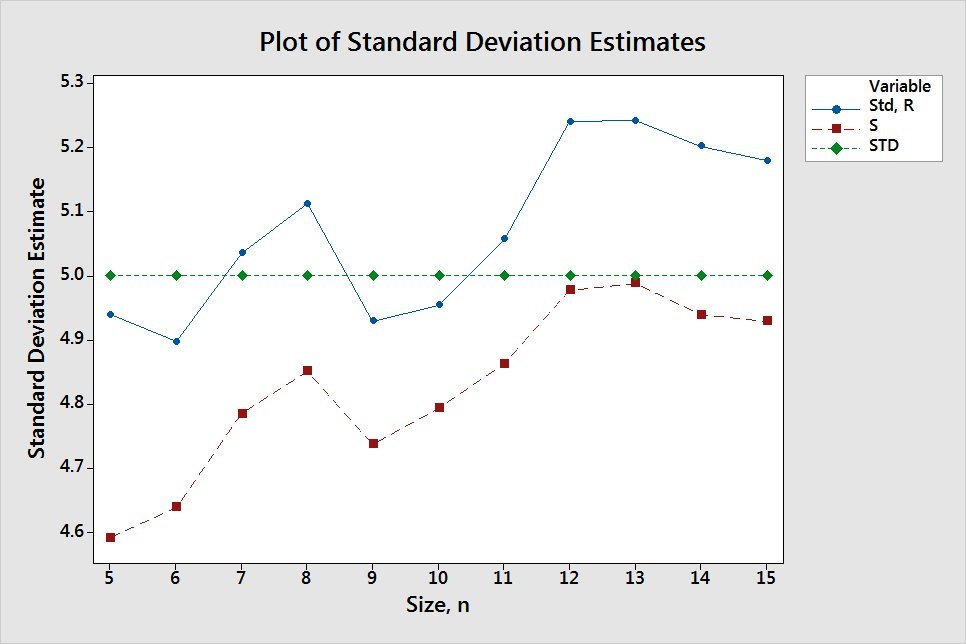

Plot the LCL, UCL, centerline, and subgroup means.Find the UCL and LCL using the following equations:Ī(2) can be found in the following table: n A(2) n A(2) 2 1.880 6.Find the mean of each subgroup XBAR(1), XBAR(2), XBAR(3)… XBAR(k) and the grand mean of all subgroups using:.RBAR can be considered a reliable estimate of the range, the process standard deviation can be estimated using:ĭ(2) can be found in the following table: n d(2) n d(2) 2 1.128 6 2.534 3 1.693 7 2.704 4 2.059 8 2.847 5 2.326 9 2.970 Once the R chart is in a state of statistical control and the centerline.Do NOT eliminate subgroups with points out of range for which assignable causes cannot be found.

If not, determine the reason for the assignable cause, eliminate it, and the subgroup(s) and repeat the previous 3 steps. Plot the subgroup data and determine if the process is in statistical control.LCL=D(3)RBAR with D(3) and D(4) can be found in the following table: Find the UCL and LCL with the following formulas: UCL= D(4)RBAR and.Find the centerline for the R chart, denoted by.Find the range of each subgroup R(i) where R(i)=biggest value – smallest value for each subgroup i.3, 4, or 5 measurements per subgroup is quite common. Select k successive subgroups where k is at least 20, in which there are n measurements in each subgroup.If the R chart validates that the process variation is in statistical control, the XBAR chart is constructed. Theoretical Control Limits for XBAR ChartsĪlthough theoretically possible, since we do not know either the population process mean or standard deviation, these formulas cannot be used directly and both must be estimated from the process itself.

0 kommentar(er)

0 kommentar(er)